Certified quality for water screen

The range of Paparelli products includes all that is necessary to the formation of a well column: casings, spiral screens for water wells, in particular "Wedge Wire Screen" filter, bridge slotted screens, simple slotted screens with every piece of junction (such as collars, flanges, reduced flanges with holes, threads) and particular pieces like well heads, centralisers, bottom caps, dielectric joints, conical reductions.

Casings and bridge slotted screens are obtained from calendared sheet with thickness from 3 to 10 mm. This type of working allows manufacturing every diameter so as to satisfy all the requests, from a minimum diameter of 114 mm. All the manufactures can be realized: in carbon steel (FE 37 – FE 52) which can be crude (and so with a black rolling) or painted/bituminised or galvanized and in every type of stainless steel according to its final use (304, 304L, 316, 316L, 1.4462, 430 and so on). The raw material, supplied by European suppliers, can be completed with chemical and mechanical analysis certificates if necessary or requested.

The choice of the material forming the well column (casings and screens) is made just considering its final use (drinkable, irrigation, desalination, thermal centres, dispersant wells, industry, research and so on), to its geological and stratigraphical situation, to the operative conditions of drilling, to the chemical aggressiveness of water and to the corrosion phenomena (very frequent caused by stray currents).

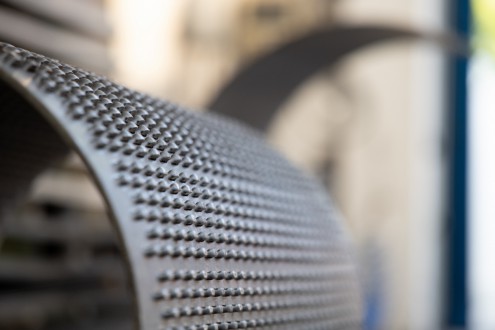

The added value of Paparelli is the production of wire which allows to obtain trapeziums and triangles of any dimension and therefore suitable to produce spiral screens that can bear resistances to squashing and traction, thus avoiding, as far as possible, the use of screens with inside casing. The latter are indicated for the installation to high depths, in grounds with particular features where they are preferable to the spiral screens and where the specifications require them.